The right control system can transform material handling safety from a regulatory hurdle into a true operational advantage. In this guide, you’ll discover how OSCO Controls delivers next-level safety in control systems, compliance, and innovation through every phase of your operation.

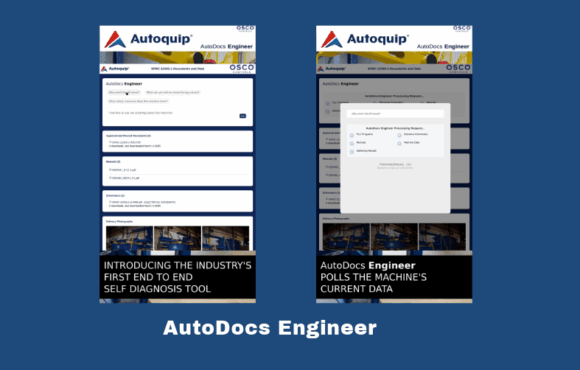

OSCO Controls Enhances AutoDocs with Virtual Assist Support

One year ago, OSCO Controls introduced AutoDocs—a groundbreaking tool that delivers instant access to project documents by simply scanning a QR code...

Manual vs. Automated Control Systems in Material Handling

In today’s fast-paced industrial landscape, the way you control your material handling processes can make or break your operation. As technology advances, businesses face an important choice: stick with tried-and-true manual process control systems or embrace automated control systems that promise greater efficiency and insight. Understanding the pros and cons of manual and automated systems is essential for making the right investment in your facility’s future.

Thank You for a Fantastic Year!

Dear Valued Customers, As we wrap up another incredible fiscal year, I want to take a moment to extend my deepest gratitude...

Upgrading Material Handling Control Systems for a Competitive Edge

In this blog post, we’ll explore the critical reasons for upgrading your control systems, show you how to recognize when it’s time for an overhaul, and walk you through the upgrade process.

Case Studies: Successful Industrial Automation Projects

At OSCO Controls, we pride ourselves on delivering advanced automation solutions that drive efficiency, enhance safety, and generate measurable ROI for our...