Online Retailer Drives Productivity with High-Performance Control Systems

Challenge

Major online retailer built a new distribution center to keep up with their growing demands. OSCO Controls helped by designing a high-performance control system to integrate with their freight elevators. Simple to use control operations are needed for employees who will be using the equipment to move product to and from upper levels.

Solution

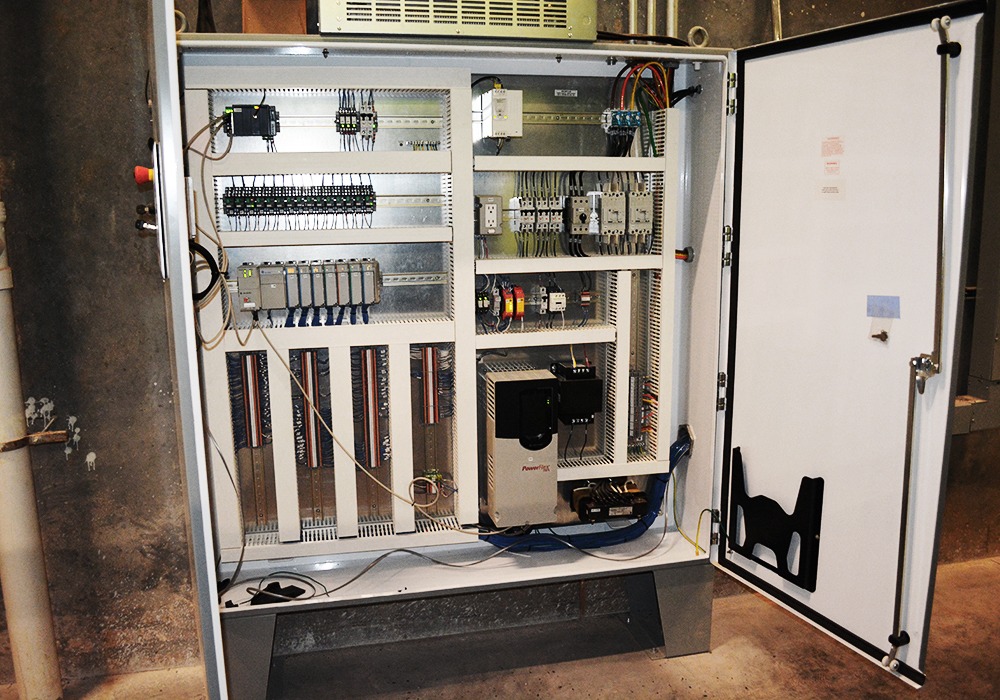

OSCO Controls custom built an internally pre-wired, NEMA 12 rated control panel with appropriate transformer, overload relay, field wiring terminal block and appropriate breakers. PLC programming controls the equipment and communicates to the motor controllers to call / send the lift. HMI software provides real-time lift status and equipment alarms to operations. Cloud-base technology using Ethernet I/P provide troubleshooting and equipment history information. HMI Panels with the following functions: • Lift status and location • Maintenance mode access • E Stop reset • External data port for laptop access and troubleshooting Control Stations: Each operating floor is equipped with a light-present momentary contact push-button control station with the following functions: • Call/Send push buttons for each floor. Button shall light green when activated. • Mushroom style E-stop switches with red light after activation. • Fault indication per floor included.

Result

Employees of the online retailer benefit from a reliable system built on modern technology that is easy to use and maintain. The control system provides a high level of visibility to personnel who use the freight elevators allowing them to interact with the equipment to monitor performance. • Self-diagnostic for maintenance issues • Lift Status: floor location • Push Button Controls with Light Status Indicators