Let’s learn more about how OSCO partners with OEMs to simplify the path from idea to implementation.

Let’s learn more about how OSCO partners with OEMs to simplify the path from idea to implementation.

At OSCO, we understand the complexities of specialized control panels and their importance to an OEM’s high-volume environment. OSCO Controls has been an industry-leading designer and fabricator of custom control panels for over 30 years. But our skills don’t stop there!

Manufacturers require advanced controls to ensure consistent levels of productivity. Read on to learn more about how OSCO converts challenges into opportunities in this vital industry.

As we welcome a new year, we continue to see the expanded role that technology is playing in industry. OSCO is proud to work with clients in several high-profile fields, including OEMs, recycling, utilities, oil & gas, and manufacturing...

The OEM product development lifecycle is highly complex. A product will go through several phases on its journey to becoming market ready for customers. And as new technology continues to drive innovation, control panel OEM developers are faced with creating more advanced products in order to stay competitive.

OEMs are committed to manufacturing components that deliver exceptional quality and performance to meet the requirements of any industry. A vital aspect of the overall process is ensuring that your operational requirements are executed with precision.

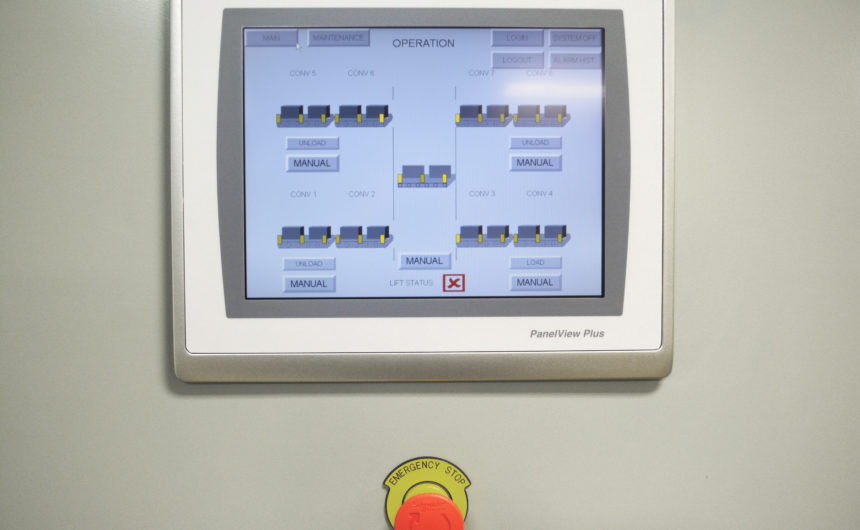

OEMs have a lot to prioritize when designing new equipment. The controls that operate the equipment can be a complicated piece of product development. OSCO Controls can help ease the burden of this part of the process by partnering with OEMs to create the right custom-engineered controls for whatever the application requires.

When high accuracy matters the most? Many industries who are using processing equipment in their manufacturing practices are looking to fulfill a functional requirement such as accumulating, sorting, repeatability, or sequencing. They need their equipment to perform these tasks to a high degree of precision, accuracy, and continuous use. For equipment control situations, we offer...