If there’s a way to reduce physical exertion while increasing options and accuracy, then using custom control panels to produce mechanical solutions must be near the top of that list. When a company comes to OSCO Controls with a request, it’s typically going to involve the creation of control panels that will help operators trigger or halt certain movements or operations. Whether there’s a need to meet National Electrical Manufacturers Association (NEMA) ratings, design and creation of a custom control panel or programming support, OSCO Controls can help a wide variety of industries get the job done. To learn more about the specific offerings of an OSCO control panel, we’ll use this blog to explain features that can assist operators who’ll be saving time and effort as a result.

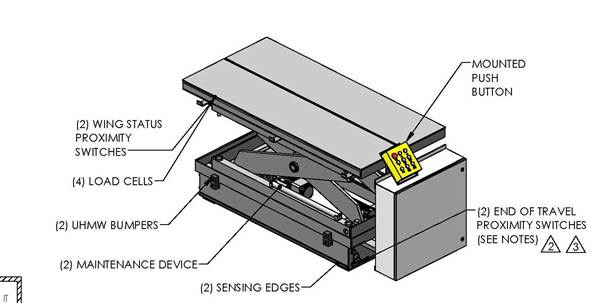

One piece of equipment that has benefited from an OSCO-designed custom control panel is a maintenance device that is used to load reams of paper onto a processing line. This equipment is then capable of transporting the paper rolls to the other end of the processing line by moving a lift. The control panel itself is capable of operating the lift, tilter and transport base. (Readers may view a diagram and picture of this piece of machinery in this blog post.) The control panel operates the lift; tilter; “Vdeck” wings individually, which are located on the top of the platform; and the transport base. Buttons on the panel operate the controls. By pressing and holding the “lift up” and “lift down” buttons, the machinery will be raised and lowered. The “wing 1 up,” “wing 1 down,” “wing 2 up” and “wing 2 down” will have a similar effect on the individually-operable wings. The “forward” and “reverse” controls will move the transport base.

Since OSCO Controls is well-versed in VFD and PLC requirements, end users will have the ability to control electric motors with just the right speed required to operate the equipment. OSCO is also adept at building panels for original equipment manufacturers (OEM) that can handle multiple functions and tasks. This means large-scale operations can come to OSCO with their needs and this company, which has been in business since 1992, can craft a solution. Similarly, companies who need a one-time-only development of a control panel to help workers manage routine movements of massive pieces of equipment are encouraged to contact OSCO. In the end, every customer will be able to push a button and turn on or off fan motors, forward and reverse travel, tracking, lights, elevation and more.