This year OSCO Controls will celebrate its 30th year in business. We could not be more excited to be celebrating this milestone. As we close out our fiscal 2021/22, it is amazing to reflect on all that we have accomplished the last 30 years.

This year OSCO Controls will celebrate its 30th year in business. We could not be more excited to be celebrating this milestone. As we close out our fiscal 2021/22, it is amazing to reflect on all that we have accomplished the last 30 years.

OSCO Controls is an industry-leading provider of innovative control panel solutions. We are dedicated to delivering safe and reliable products that exceed our customers’ expectations. We’re proud to share our industry certification and affiliation information with you as we build to UL508A standards!

OEMs are committed to manufacturing components that deliver exceptional quality and performance to meet the requirements of any industry. A vital aspect of the overall process is ensuring that your operational requirements are executed with precision.

As a manager on the facility floor, your number one priority is to make operations as seamless as possible. This can be achieved by implementing a system of electrical control panel designs custom-suited for your specific project. Custom Control Panel Design: Our Process A UL-listed 508A panel fabrication company like OSCO Controls offers custom control...

Happy Holidays from the entire team at OSCO Controls We are grateful for customers like you and thank you for your trusted support.

OSCO will be closed starting Dec. 23 through Jan. 2.

OSCO Controls is pleased to announce Brad Fury has joined the company’s team as Controls Engineer.

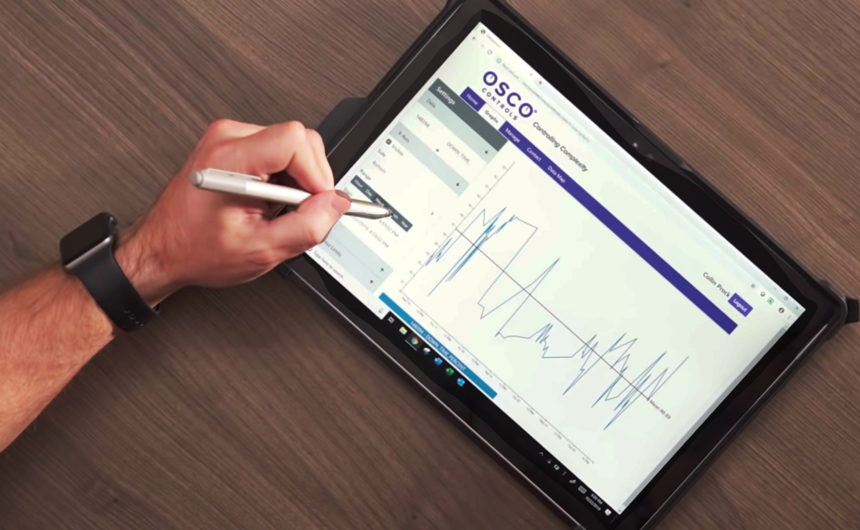

As your warehouse grows, it’s crucial to streamline your equipment’s programming across the board. A custom and well-designed Human-Machine Interface (HMI) can reduce operating costs, downtime, make it easier to maintain equipment, and provide more transparency throughout your organization.

Distribution and warehouse automation requires organized systems put in place. It’s important to have the experience and knowledge to maximize these services. Whether it’s a new facility development or upgrading an existing system, OSCO Controls provides process control solutions that maximize distribution and warehouse automation.

OEMs have a lot to prioritize when designing new equipment. The controls that operate the equipment can be a complicated piece of product development. OSCO Controls can help ease the burden of this part of the process by partnering with OEMs to create the right custom-engineered controls for whatever the application requires.

OSCO Controls announces significant growth achieving 5X increase in revenue and a remarkable 5X increase in production orders since the company was acquired by Autoquip Corporation in 2016. The relocation to their new facility in September 2019 along with corporate support has allowed OSCO to target new industries, hire new employees, and expand production capabilities.